Permanent mold casting is a metal casting process that employs reusable molds ("permanent molds"), usually made from metal. The most common process uses...

12 KB (1,545 words) - 11:13, 1 July 2024

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold (usually by a crucible) that contains a negative...

47 KB (6,249 words) - 21:50, 13 June 2024

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand—known as casting sand—as the mold material. The...

48 KB (6,827 words) - 02:27, 16 August 2024

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and...

15 KB (1,915 words) - 20:37, 15 November 2024

Plaster mold casting is a metalworking casting process similar to sand casting except the molding material is plaster of Paris instead of sand. Like sand...

6 KB (814 words) - 14:40, 26 February 2024

Spin casting, also known as centrifugal rubber mold casting (CRMC), is a method of utilizing inertia to produce castings from a rubber mold. Typically...

12 KB (1,521 words) - 04:36, 14 August 2024

to compete with bronze, cast iron and aluminium using sand and permanent mold casting methods. Distinguishing features of ZA alloys include high as-cast...

5 KB (199 words) - 15:34, 7 September 2023

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created...

39 KB (4,642 words) - 01:39, 6 November 2024

List of manufacturing processes (section Casting)

(Lost-wax casting) Countergravity casting Lost-foam casting Low pressure die casting Permanent mold casting Plastic mold casting Resin casting Sand casting Shell...

12 KB (810 words) - 23:09, 18 June 2024

Solid casting is used to produce solid articles, such as cup handles; for this the mold frequently includes a reservoir of excess slip. Hollow casting is...

18 KB (2,020 words) - 04:14, 2 July 2024

iron pipe coated on the interior with cement. In centrifugal casting, a permanent mold is rotated continuously at high speeds (300 to 3000 rpm) as the...

8 KB (874 words) - 20:52, 25 March 2024

Lanxide process Injection moulding Rapid prototyping Casting[citation needed] Permanent mold casting[citation needed] Powder metallurgy Linear friction...

2 KB (147 words) - 07:03, 29 November 2023

permanent mold at 19%; based on 2006 shipments). The exact process and pattern equipment is always determined by the order quantities and the casting design...

16 KB (2,318 words) - 21:29, 28 July 2024

Magnesium alloy (section Casting)

and AZ92 are most used for sand castings, AZ91 for die castings, and AZ92 generally employed for permanent mold castings (while AZ63 and A10 are sometimes...

37 KB (4,734 words) - 13:58, 12 November 2024

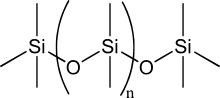

Release agent (redirect from Mold release agent)

A release agent (also mold release agent, release coating, or mold release coating) is a chemical used to prevent other materials from bonding to surfaces...

10 KB (1,305 words) - 18:01, 28 March 2024

it is made from cast iron or cast aluminium, using methods of permanent mold casting or shell molding. Experimentally, though, composite materials have...

3 KB (297 words) - 13:24, 7 January 2024

Metalworking (section Casting)

used. Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:...

39 KB (4,691 words) - 07:58, 17 November 2024

manufacturing process in which casting material is forced into a mold. Transfer molding is different from compression molding in that the mold is enclosed rather...

10 KB (1,319 words) - 08:36, 5 October 2024

alloys, from cast iron to aluminium sand casting, permanent mold and die casting up to large steel castings. The software supports the user in the modelling...

4 KB (339 words) - 12:08, 6 August 2024

handles and buckles. Permanent mold casting, an industrial casting technique focused on high-volume production, allowed smiths to reuse molds to make exact replicas...

101 KB (12,715 words) - 01:20, 21 November 2024

Rotational molding (category Casting (manufacturing))

to casting, cast molds tend to have additional costs associated with the manufacturing of the tooling, whereas fabricated steel or aluminum molds, particularly...

31 KB (4,253 words) - 13:18, 19 August 2024

Glossary of sculpting (section casting)

hard when dry. The mold is then separated to release the original sculpture. Once the mold is reassembled, at its most simple the casting material is poured...

12 KB (1,549 words) - 21:50, 5 November 2024

Glassblowing (section Mold-blowing)

the glassworker. Two types of mold, namely single-piece molds and multi-piece molds, are frequently used to produce mold-blown vessels. The former allows...

31 KB (4,086 words) - 15:14, 15 November 2024

casting processes are: Lost-foam casting Full-mold casting The main difference is that lost-foam casting uses an unbonded sand and full-mold casting uses...

5 KB (527 words) - 22:12, 1 February 2021

Standards for Aluminum Sand and Permanent Mold Castings, which provides engineering and metallurgical standards for casting alloys in metric and U.S. units...

13 KB (1,527 words) - 18:49, 5 March 2024

assembly. The metal molds can produce an unlimited number of castings. Unlike the flexible molds used for resin casting, metal molds are not adversely affected...

8 KB (1,133 words) - 17:07, 2 November 2024

Rodman gun (section Casting)

containing the gun mold, keeping the gun mold nearly red-hot. For an 8-inch Rodman columbiad, the core was removed 25 hours after casting and the flow of...

23 KB (2,759 words) - 13:58, 22 November 2024

Porosity sealing (category Casting (manufacturing))

vacuum impregnation seals are plastic and sintered metal. Die castings and permanent mold castings commonly contain internal porosity. This porosity is generally...

11 KB (1,346 words) - 20:41, 16 January 2024

Injection moulding (redirect from Injection mold)

mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses...

53 KB (5,735 words) - 17:37, 20 November 2024

cast in molds, it can form any shape. To strengthen it, coarse cloth or bagging, or fibers of hemp or jute, are put into the molds before casting. It becomes...

2 KB (218 words) - 11:40, 1 October 2024