Gold Flex

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

| |

| Manufacturer | Honeywell |

|---|---|

Gold Flex is a non-woven fabric manufactured by Honeywell from Kevlar, and is often used in ballistic vests and body armor. Gold Flex is lighter than woven Kevlar, Twaron and other Ballistic material. Gold Flex is a laminated material consisting of cross-laid, non-woven fibers in a resin matrix. The fibers are laid straight and not in a woven fabric configuration. When an object strikes this material, a "web" of its clusters absorb the impact and minimizes penetration.

Honeywell describes "Gold Shield" as being almost identical, only either using two plies instead of four, or using a different resin, depending on version.[1] Both products use Honeywell's patented "Shield" technology, which is present in their Spectra Shield.

Protection

[edit]Gold Flex gives resistance to abrasion and resists organic solvents making it non-conductive and non-flammable. Its degradation point starts at 500 °C (932 °F) and it has no melting point. It is sensitive to salts, acids, and ultraviolet radiation. GolfFlex also causes static build up. Protection is also based on the pressure of the impact. Some of these fabrics are only designed with hand-guns in mind basically making anything with a bigger caliber a threat potential. One cannot wear a GoldFlex and expect a large caliber round (E.G .50 BMG round) to be stopped from penetrating it. Also GoldFlex is not the only material that is responsible for minimizing penetration and absorbing the attack. Along with GoldFlex there are other layers on top of this fabric to ensure that the object does not penetrate through the material.

Armor

[edit]When a bullet strikes the body armor, it hits ballistic fibers which are strong enough to not penetrate through. This fiber absorbs and disperses the impact that has been made by the bullet to the body armor. This process continues and every layer of this material is effected until the bullet has come to a full stop. All layers combined form a larger area of the impact to disperse and keep the bullet from penetrating the carrier. This helps in reducing the risk of blunt force trauma.

Production

[edit]| Characteristics | ||

|---|---|---|

| Roll Weight | Pounds | 122.7 |

| Width | Inches | 63.0 |

| Length | Feet | 492 |

| Total Area Density | Testing Method | ASTM D3776-96 (2002) |

Comparison with other materials

[edit]

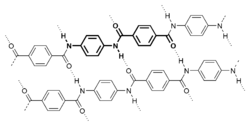

Kevlar Chemical Composition | |

|---|---|

A Chemical Structure of the fabric used in a Kevlar |

Kevlar is five times stronger than steel of equivalent weight. It was invented by a Polish-American chemist Stephanie Kwolek and introduced in the 1970s. It is used for body armor and racing tires but is more expensive than Gold Flex. Twaron is another alternative to Gold Flex but is not much in demand. Occasionally several materials are used in one product.

See also

[edit]References

[edit]- ^ "Gold Shield®". advancedmaterials.honeywell.com. Retrieved 2024-12-11.

- [2]

- Aramid

- Ioffe Institute Databases

- WebElements.com

- ChemSpider - The free chemical database, The Royal Society of Chemistry

- Honeywell manufacturer of the Gold Flex fabric.

- About Gold Flex.

- Information

- "Bullet Proof Shop". Bullet Proof Shop. Archived from the original on 22 January 2011. Retrieved 4 April 2013.

- "Rhino Armor". rhino armor. Archived from the original on 15 April 2013. Retrieved 4 April 2013.

- "Blanket of Gold Flex". interamer. Retrieved 4 April 2013.

External links

[edit]- EINECS (European INventory of Existing Commercial chemical Substances)

- Ratio International Corporation Crystal Structure Catalogue

- https://web.archive.org/web/20101120153843/http://cas.org/products/sfacad/index.html

- http://webbook.nist.gov/chemistry/

- Spectral Database for Organic Compounds, SDBS Archived 2013-01-14 at the Wayback Machine

- http://chemfinder.cambridgesoft.com/ Archived 2013-04-11 at the Wayback Machine

- http://www.astm.org American Society for Testing and Materials (ASTM)

French

French Deutsch

Deutsch